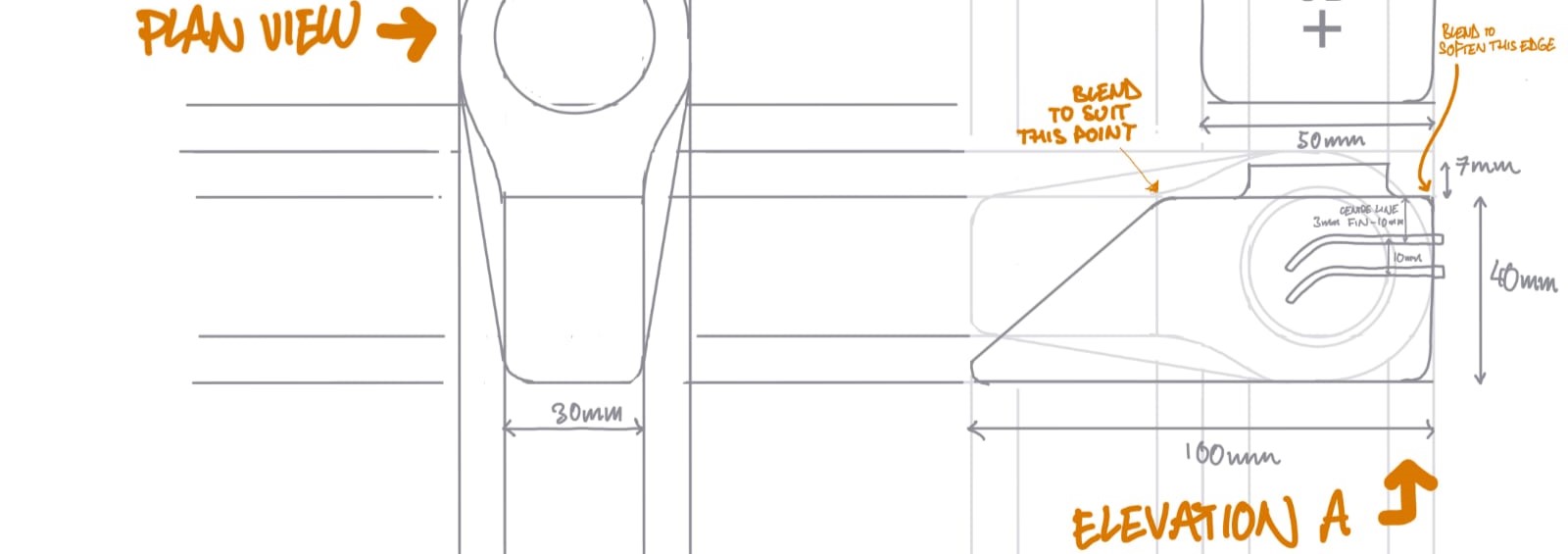

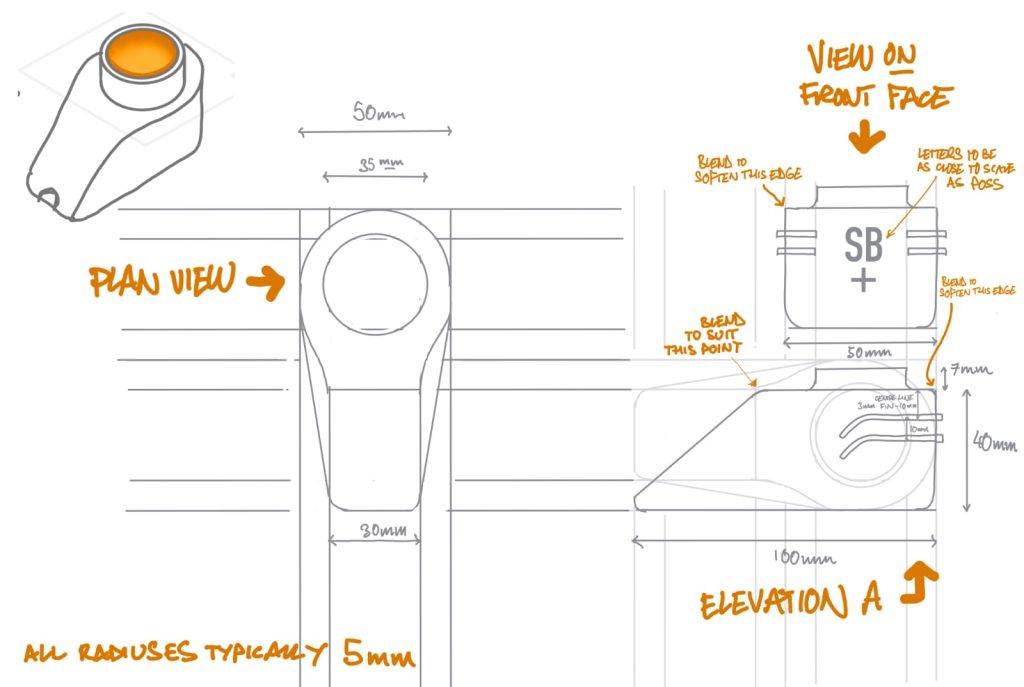

Our customer’s customer had an idea for a component in their head they wanted to be made from cast aluminium. They put down the idea onto a piece of paper with some key dimensions and that’s where we began. The hand drawn image was recreated in CAD.

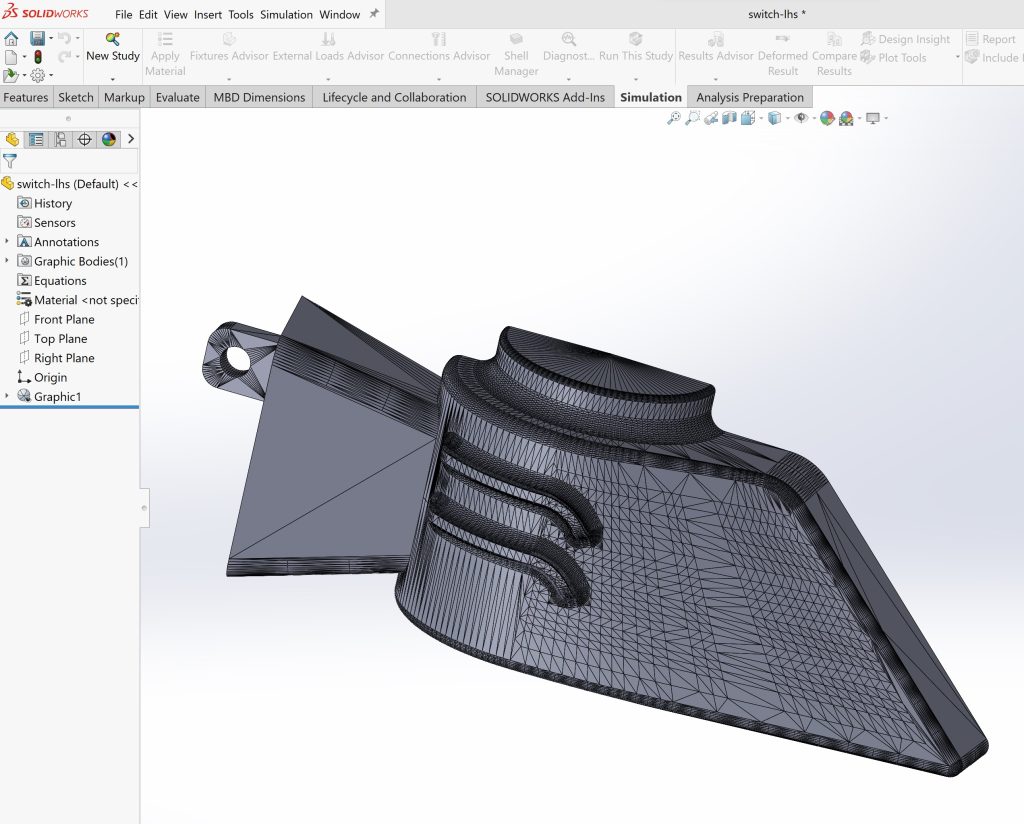

Numerous iterations of the design were made based on feedback from the customer. The purpose for this CAD data was to produce bucks used to create patterns which are in turn used to cast the finished product in aluminium. Therefore the actual component design had to be adapted to create draft on vertical sides, radii on internal corners and edges, multi-part design to allow certain features to be created – all required for the metal casting manufacturing process.

The bucks were 3d printed by Mark at All3dlabs using PA12. Additional, removable tabs were added that are used to hang the parts during 3d print post process that creates an excellent surface finish.