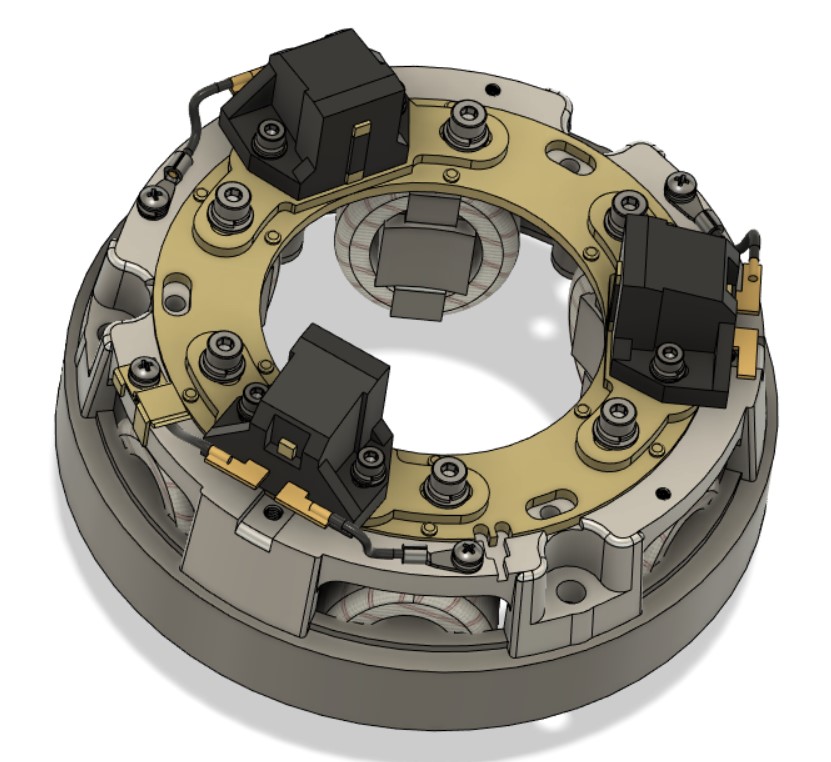

Rex’s Speed Shop (RSS) had a requirement to create a digital twin of some of their products. This digital information could then be used to manufacture parts, produce installation and instruction manuals, integrated parts catalogues and other promotional materials. RSS manufactured the physical parts but didn’t have all the digital twin data. As part of ongoing development of ignition products for Kawasaki triples, one of the first projects was to reverse engineer an RSS stator assembly.

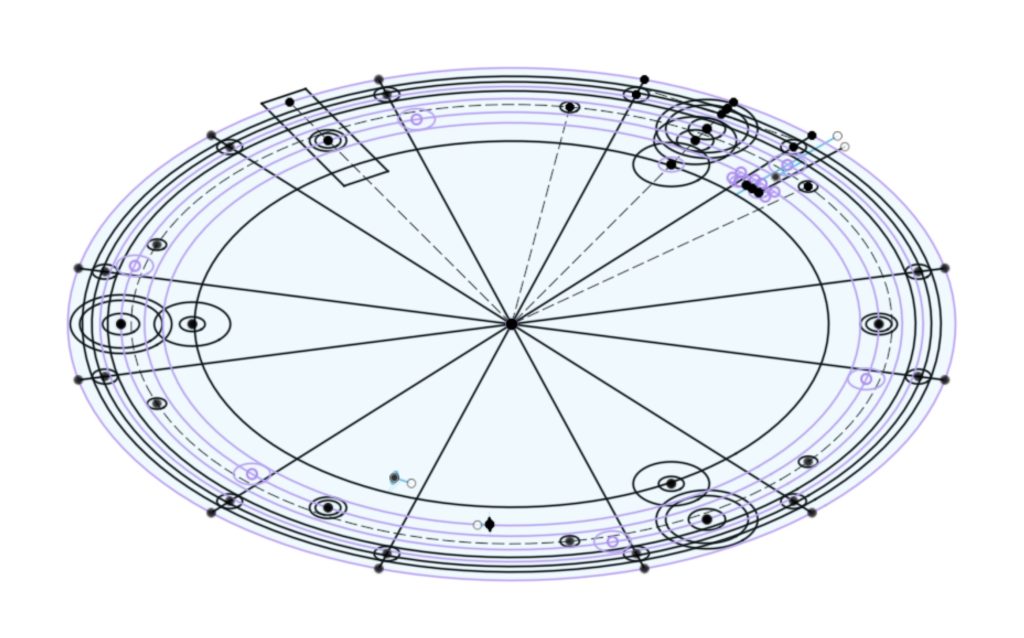

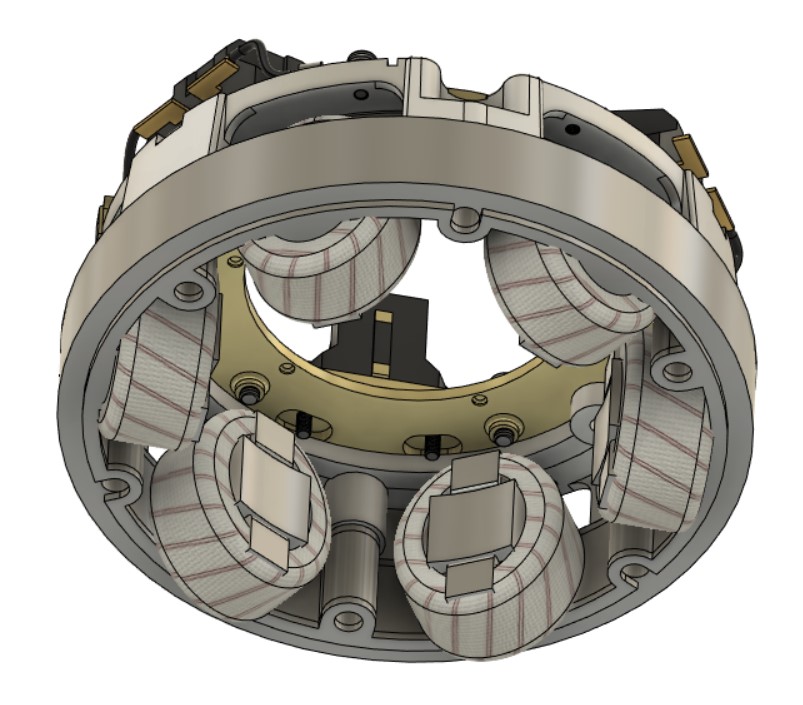

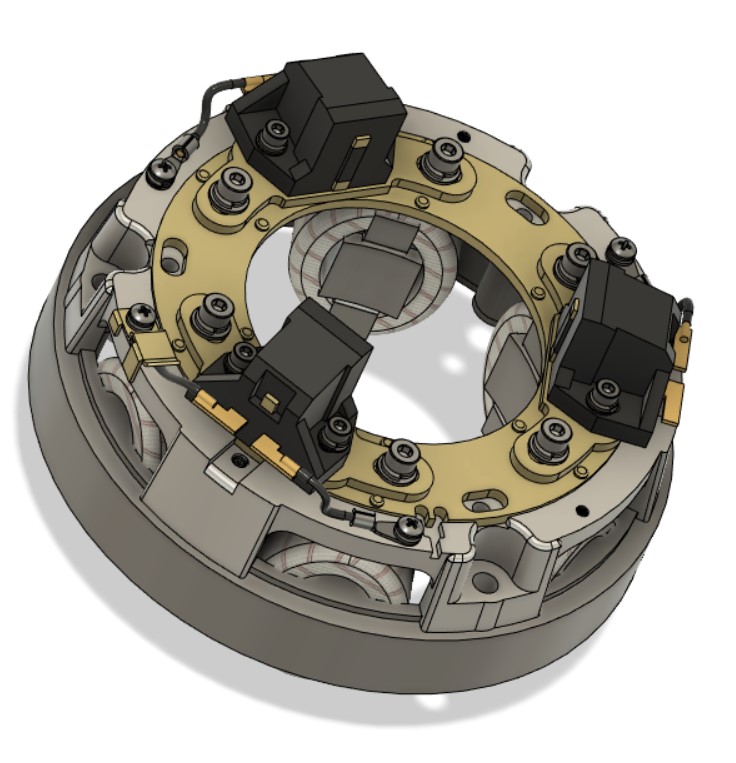

RSS provided physical versions of all their stator components. Each of these were measured and then digitised in CAD software. Once complete, discrete components were arranged into finished assemblies.

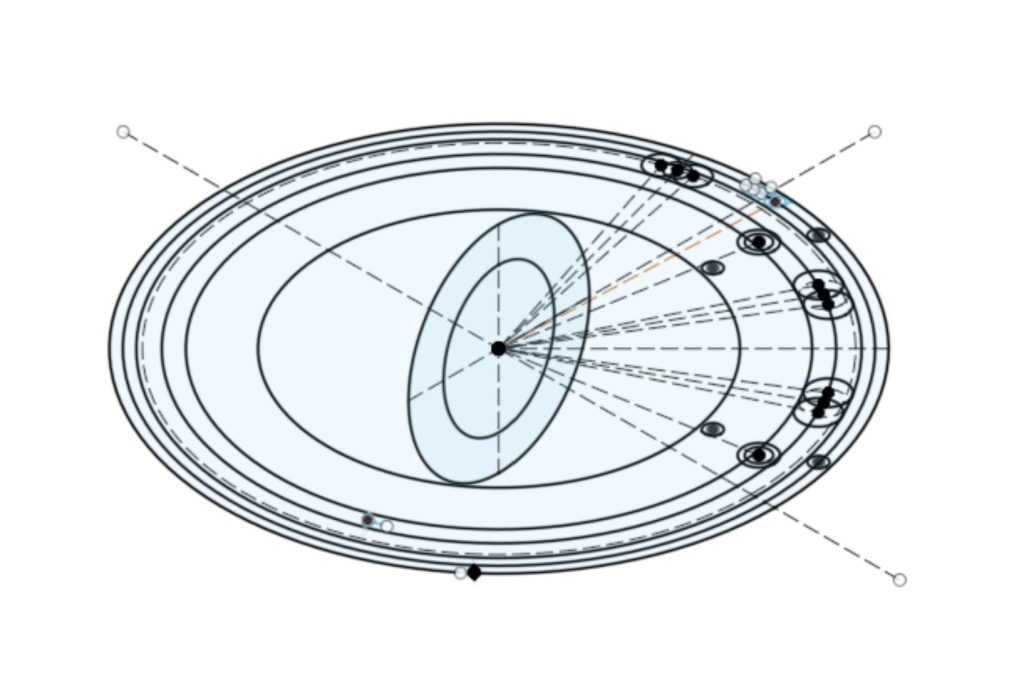

These assemblies could then be shown in exploded views with each part identifiable, a full bill of materials including RSS part numbers to assist with online store integration, spare parts ordering, instruction manuals, etc.